This article describes our experience with SOUTHERN SPINCASTING LLC.:

Entity:

SOUTHERN SPINCASTING LLC

779 County Road 55

Clanton, AL 35046

(205) 217-3744

Subject:

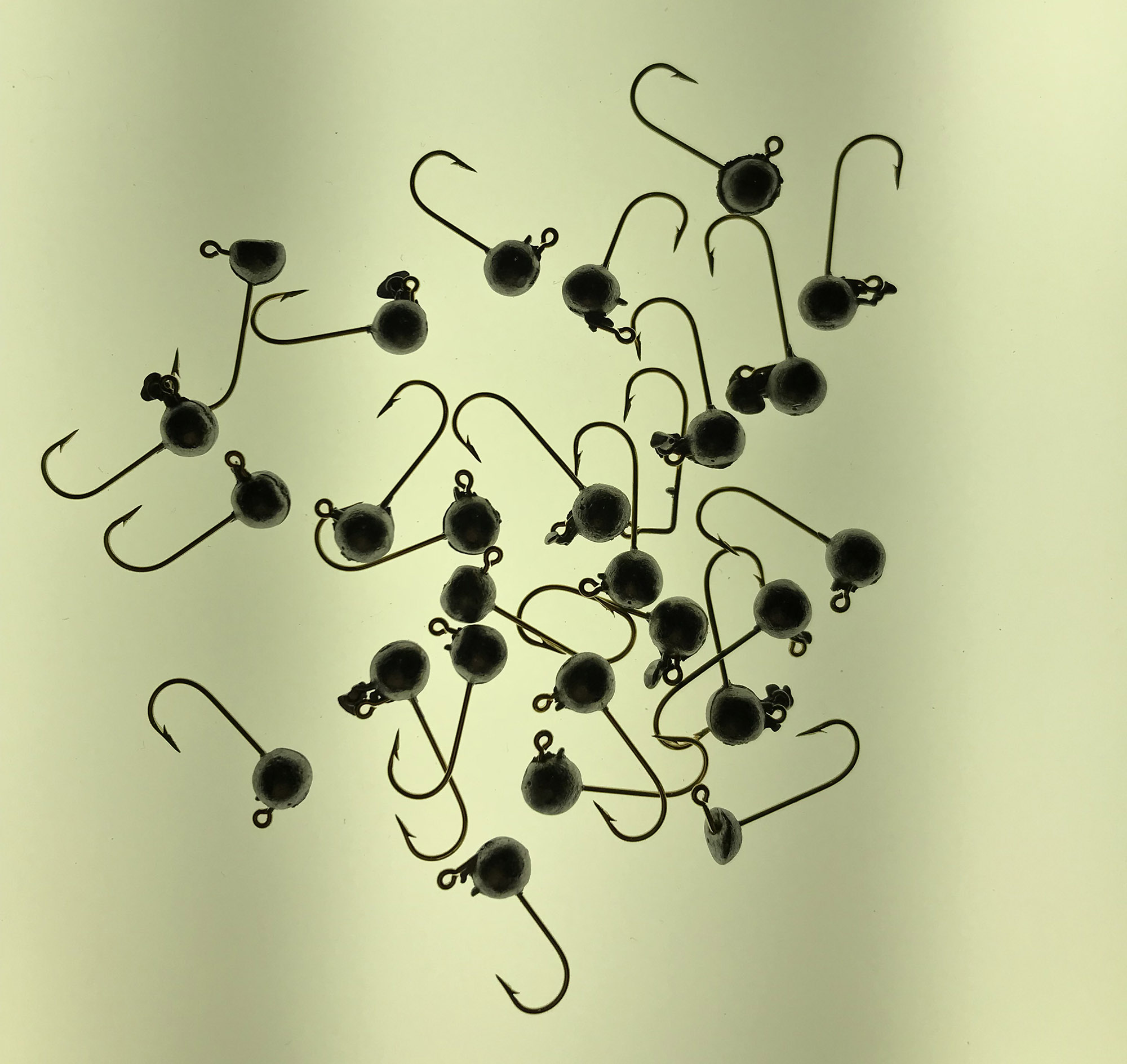

1/32-ounce jig heads, number 8 gold hook unpainted.

Summary:

10/1/2018, prepaid $300 for two nine-inch spin-cast molds.

10/19/2018, purchase order issued for 10,000 unpainted 1/32 nd ounce jig heads, number 8 gold hook.

11/19/2018, items received.

It was not possible to count the received items by weight as there was no consistency from piece to piece. Completing a time-consuming count by hand was necessary due to these inconsistencies. As the jig heads were being prepared for painting, an unacceptable number of rejects were found.

Our purchase order was issued for 10,000 pieces. We received 9,687 pieces. Of this number, 2685 were rejects. That’s nearly a 28% reject rate. In addition to this unacceptable reject rate, any good castings were as much as 14% heavier than the samples we sent to SOUTHERN SPINCASTING LLC. for the purpose of spin-cast mold assembly.

Other issues with the pieces received included:

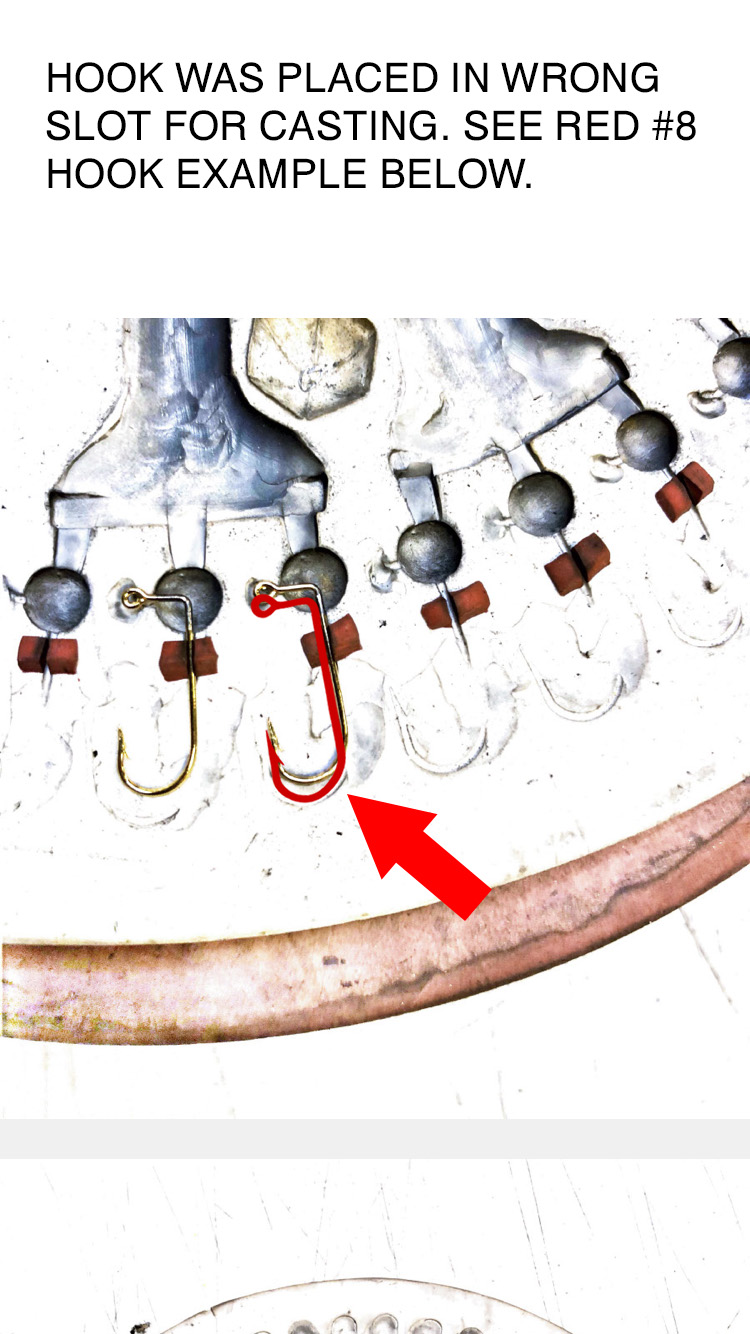

• HOOKS SET IN VARIOUS LOCATIONS OF THE JIG HEADS

• LEAD RUNNING DOWN SHANK OF HOOK AND UP TO EYELET

• LEAD IN EYELETS OF HOOKS

• UNACCEPTABLE FLASHING

• HALVES NOT ALIGNED

• INCOMPLETE CASTING

See images below:

These are just a few images of the many issues described. Additional images are on-file.

Conclusion:

Our customer rejected the entire batch. We scrapped this batch of jig heads.

We requested SOUTHERN SPINCASTING LLC. to return our two nine-inch spin-cast molds, as we had no confidence that SOUTHERN SPINCASTING LLC. was capable of casting small jig heads.

Upon inspection of these molds, we found that, even though we paid SOUTHERN SPINCASTING LLC. for new molds, the molds returned to us had endured many cycles and were at the end of their life cycle. Two new spin-cast mold should easily yield 500k pieces of an item this small. We had just 10k pieces cast.

The sample jig heads we sent to SOUTHERN SPINCASTING LLC. for the purpose of building new molds, included 1/32-ounce heads with number 8 hooks. The molds returned to us were originally made for a slightly larger hook and slightly larger head. There is no doubt the castings sent to us came from these molds. It appears as if a blade of some sort was used to gouge out a space to accept a number 8 hook. Throughout the casting process, apparently the operator placed the jig hooks in the carved hook locations and in the locations original to these molds. It’s obvious these molds were made previous to our first order, as they were modified to accept a number 8 jig hook, and were not made specifically for a number 8 jig hook. These modification, and the fact the spin-cast molds were at the end of their life-cycle, yielded substandard castings. Essentially, SOUTHERN SPINCASTING LLC. duped us out of the $300 mold charge.

Our contact with SOUTHERN SPINCASTING LLC was ROGER PERKINS. Mr. Perkins acknowledged rejects in this batch, but claimed to have no knowledge to what extent the issue was. Mr. Perkins offered to re-cast the rejects we had found, but our customer had already rejected the batch due to the gross head size/weight discrepancy and hook placement.

This was our first, and last transaction with Mr. Roger Perkins of Southern Spincasting LLC.

Photographs, telephone phone conversations and emails are all on file to support this claim.